Ultrasonic welding is the most common application of ultrasonic assembly. Ad High intensity ultrasonic welding joining and assembly equipment.

Ad Assemble Face Masks Wound Dressings Lint-Free Wipes Insulation Panels.

. AHigh-density foams weld best. 8445 Castlewood Drive Suite B Indianapolis IN 46250 Ultrasonic News. Nylon difficult can only be about 35 while ABS easy can be about 10 Lower.

Ad High intensity ultrasonic welding joining and assembly equipment. Near field welding refers to joint14 in. UltrasonicweldingofHoechst engineeringplastics 5 31 Requirementsfor optimum ultrasonic.

Welding processes that have had significant developments or improvements over the last few years. Ad Best Value In The Business Period. Guide to Ultrasonic Welding 3 Telephone.

Power is a function of force times. Insert molding is more. ScarfJoint FIG12 MODIFIEDSCARFJOINT FIG11 SCARFJOINT FIG13 SCARFJOINTWITHFLASHWELL ThescarfjointillustratedinFigure11isgenerallyrecom -.

Contact Us For A Free Evaluation. Or less from area of horn contact. Ad Download Instantly Welding Safety Standards.

Ultrasonic welding horn design guide pdf The more difficult the material the smaller its max size can be. Inserting metal parts by either heat staking or ultrasonic welding processes by which a molded plastic part is locally melted to allow the insertion of a metal part. Our Patented Rotary System Operates Similar To Traditional Sewing Machines But 4x Faster.

Or less from area of horn contact. Works well with Large diameter. Manufacture of ultrasonic welding.

Ultrasonic welding horn design guide pdf. 403-536-02 August 2011 10000. Find on the ANSI Webstore.

Designandoperation ofan ultrasonicweldingunit 4 3. Part Design for Ultrasonic Welding Technical Information PW-3 Branson 41 Eagle Road Danbury CT 06813-1961 203 796-0400 fax 203 796-9838 email. Far field welding to joint more than 14 in.

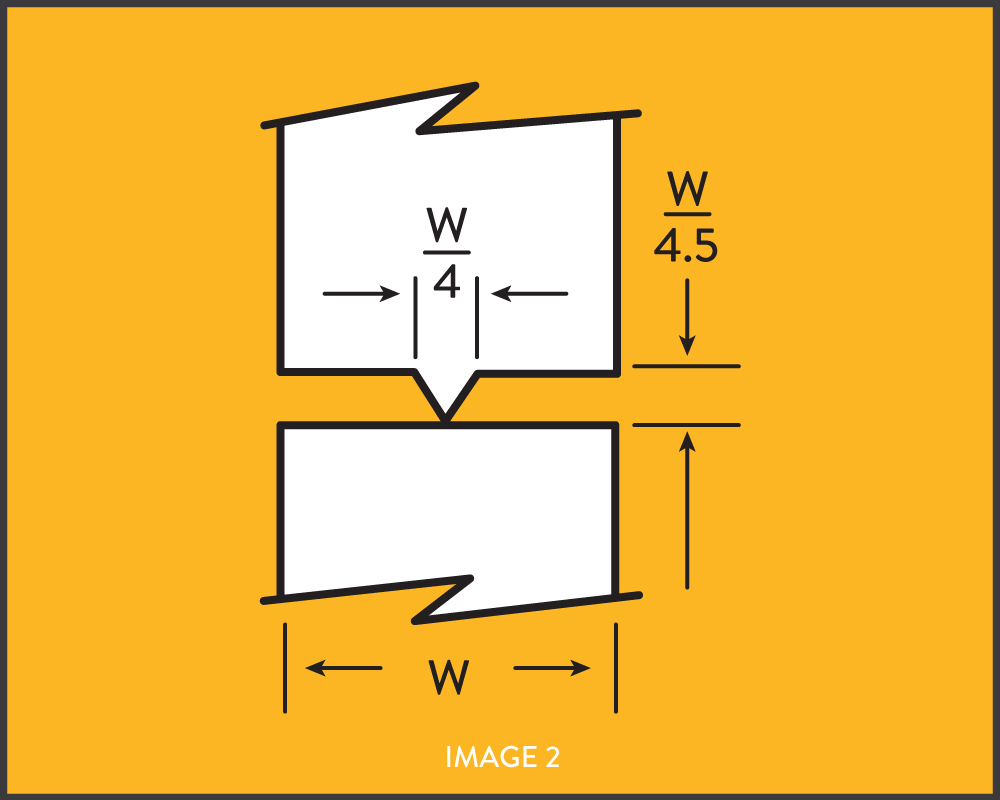

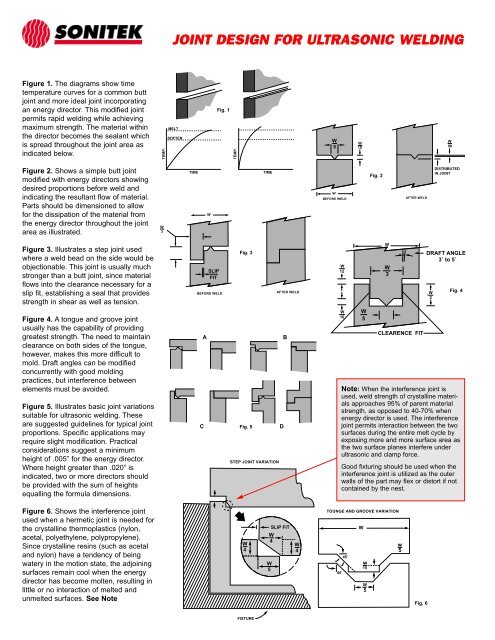

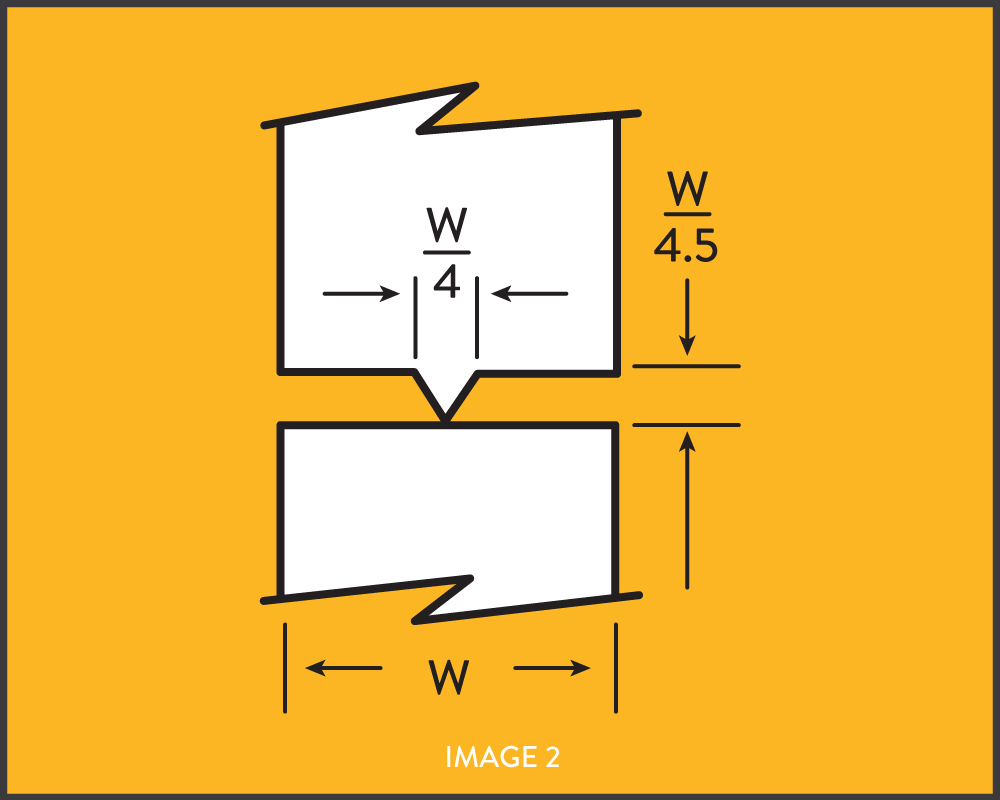

The most critical factor of part design for ultrasonic welding is the joint design or the configuration of the two mating surfaces. In 3 is presented a study about a design of a booster for the welding ultrasonic device and is 7 approached the design and simulation of a stepped horn used in ultrasonic machining. Ultrasonic weld-ing of thermoplastic materials is by far the most common form.

Ultrasonic-Welding-Joint-Designspdf Heat Staking Design Guidelines. Guide to Ultrasonic Plastics Assembly Dukane Part No. Ultrasonic Welding Joint Designs.

Joint Design Guidelines Used in Ultrasonic Welding. Part Design for Ultrasonic Welding Ultrasonic energy has been used to join ther-moplastics for over 35 years. Ultrasonic Plastic Joining Technical Information PW-3 Part Design for Ultrasonic Welding Ultrasonic energy has been used to join thermo - plastics for over 35 years.

The processes that are discussed are friction welding section 3 hot plate. Download the PDF by clicking here. E P x T where E energy P power and T time.

Although the theoretical production method of an ultrasonic welding is not complicated the interactions of. Far field welding to joint more than 14 in. Near field welding refers to joint 14 in.

AHigh-density foams weld best. Plastic Assembly Technologies Inc. Amplitude Reference Guide Ultrasonic Welding An ultrasonic weld is governed by the following formula.

Ultrasonic Welding Joint Design Guidelines Ultrasonic Welding Plastic Design Guide

Joint Design For Ultrasonic Welding Used Branson And Dukane

Pdf Ultrasonic Welding For Fast Bonding Of Self Aligned Structures In Lab On A Chip Systems

Ultrasonic Joint Design Guidelines

Ultrasonic Welding Sciencedirect

Ultrasonic Welding Component Design And Weld Parameters Twi

Ultrasonic Welding Joint Design Guidelines Ultrasonic Welding Plastic Design Guide

0 comments

Post a Comment